CASE STUDY: Why it is not recommended to install a galvanised product with stainless steel connector plate nail or vice versa?

CASE STUDY: Why it is not recommended to install a galvanised product with stainless steel connector plate nail or vice versa?Often in the timber connector industry, most timber connector companies regularly recommended that stainless steel products should never be fixed with galvanised fasteners – nails, screw etc. and vice versa. VUETRADE uphold this practice and always advise only galvanised nails/screws are used on galvanised product and stainless steel fasteners on stainless steel products. The purpose of this practice is to reduce, if not eliminate the risk of galvanic corrosion the connector product which will compromise the strength of the timber connector. This article discusses in detail on the principle of galvanic corrosion and provides a good understanding of the need for using the correct fasteners in connector application to reduce risk of corrosion.

Read the full report below or download the PDF here:

CASE STUDY: Material Corrosion PDF

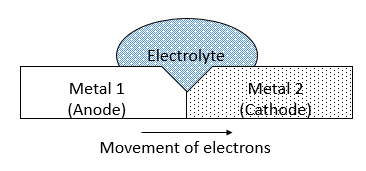

Galvanic corrosion will only occur if the following 3 conditions are satisfied:

When all 3 conditions are met, a complete electric circuit is formed; metal 1 as the anode will be ‘attacked’ preferably while metal 2 – cathode will be protected from corrosion attack. This principle has been widely used in the galvanised zinc coating on steel where zinc acts as sacrificial anodes that protects the steel base from corrosion.

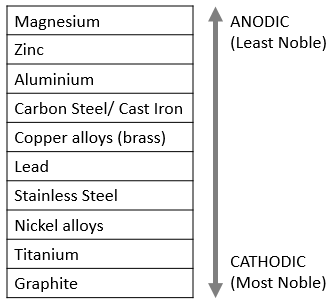

This chart shows the general arrangement of different metal material in terms of ‘nobility’ or difference in potential. In order for galvanic corrosion to occur, two metals in contact must have different potentials (one metal must be more ‘noble’ then the other). The further apart each metals in their difference in potential, the greater the corrosion rate will take place.

Meaning that if zinc-galvanised nails were used on a stainless steel connector product such as VUETRADE Stainless Steel Triple Grip, the galvanised nails will experience accelerated corrosion attack due to the large metal potential differences and compromise the overall strength of the connection joint.

The same is applied the other way around on using stainless steel connector plate nail on VUETRADE galvanised product range, however due to the difference in surface area ratio between galvanised products and the stainless steel nails, often the corrosion attack is not significant, but there are presence of electron transfer between the two metals which means corrosion attack is present in some degree.

Using fasteners of designated material on VUETRADE products (e.g. galv. nails on galv. Triple grip & Stainless Steel nails on stainless steel triple grip) effectively eliminates one of the core requirement of galvanic corrosion, since corrosion attack can not take place on contact metals with no difference of potential. These are the fundamental reasons for VUETRADE to recommend customers to NOT use galvanised connector plate nails on stainless steel products and vice versa.