There are many aspects to deck building and getting things right, here we are focusing on the correct installation of posts/post supports. We aren’t saying people are doing things wrong, but making sure you or your builder is installing the posts correctly will ensure your deck is up to standard and lasts as long as possible.

Download PDF Installation Guide

You can read here or download the VUETRADE™ Installation Guide on the link above.

Depending on the load and dimensions of the deck, footing requirements and measurements do vary. These requirements include the depth and diameter of each individual footing and the distance between them. All of these information is available in AS 1684 and AS 2870. However, a quicker and cheaper alternative is enquire with the local building authority, to save the hassle of buying and going through the Australian Standards.

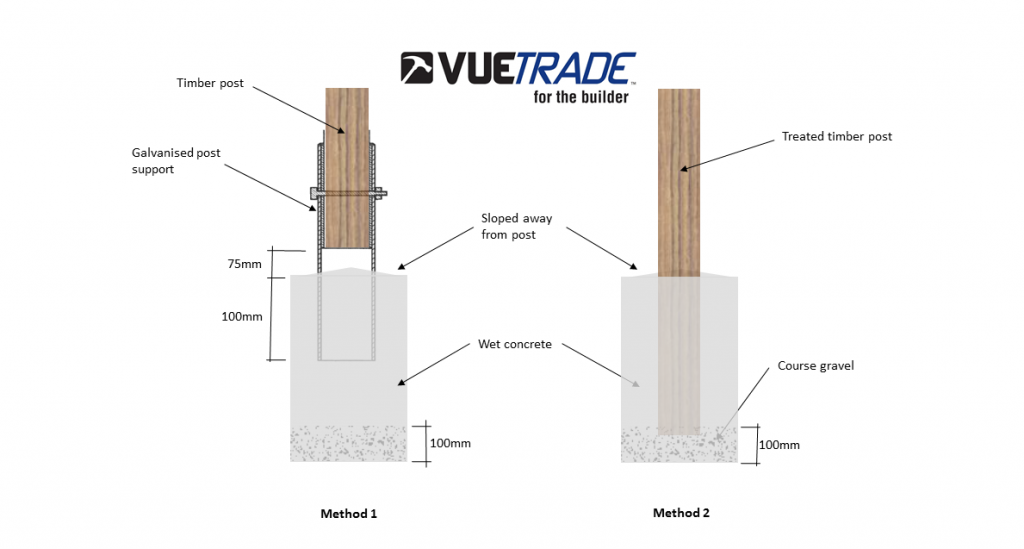

There are two different ways of casting concrete footings.

Method 1: Embed a VUETRADE™ Post Support into wet concrete. A 75mm minimum clearance between the post to the base support is required by the Building Codes of Australia (BCA) and Australian Standards, illustrated in Figure 1 and the stirrup needs to extend to at least 100mm into the wet concrete to be able to achieve its respective design capacities. The 75mm clearance acts as a termite inspection zone for local building authorities and also to increase the lifespan of the post.

Most common error occurs when the galvanised post stirrups are embedded into the concrete without clearance from the base which causes the timber posts to be in direct contact with the concrete. Concrete absorbs moisture, keeping the posts moist. This can potentially cause premature rotting in the timber post which results in a decreased performance its structural integrity. A list of VueTrade™ products are tabulated in Table 1.

Method 2: Embed the post into the concrete footing. To do so, BCA states that the holes for the embedded posts is filled with 100mm depth of coarse gravel before backfilling with concrete, shown in Figure 1. However, this method is not recommended as only specific species of timber are allowed to be embedded into wet concrete.

Table 1: VUETRADE™ Post Supports

| Purpose | Existing Concrete Substrate | Set into Wet Concrete | |||

|

VUETRADE™ Products

|

Bolt Down Post Supports |

T Blade Post Supports |

Full Stirrup Post Supports |

Cyclonic Post Supports |

Bladed Post Supports |

| Dimensions Available | Galvanised

Stirrup Size: 90mm, 100mm, 115mm, 125mm Stirrup Size: 90mm, 100mm, 115mm, 125mm 135mm, 200mm |

Galvanised

Size (mm): Four sizes to suit posts from 90 to 200 square Size (mm): Four sizes to suit posts from 90 to 200 square |

Wide range of sizes in both Galvanised and Stainless Steel available. | Wide range of sizes in both Galvanised and Stainless Steel available. | Galvanised

Heights: 125mm, 300mm Heights: 125mm, 300mm |

Share on Facebook

Share on LinkedIn

Share on Twitter

Share on Google+