The use of the word “Hoop Iron” amongst builders, trade centres and suppliers has become common and almost defining what products are being used, in Structural & Non-Structural applications. What builders and Trade Stores call Hoop Iron, can sometimes be easily mismatched with what suppliers have defined as Strapping or Bracing. Do we really know what is what? VUETRADE as a market leader in innovative products, intended to inform our builders and trade centres.

The use of the word “Hoop Iron” amongst builders, trade centres and suppliers has become common and almost defining what products are being used, in Structural & Non-Structural applications. What builders and Trade Stores call Hoop Iron, can sometimes be easily mismatched with what suppliers have defined as Strapping or Bracing. Do we really know what is what? VUETRADE as a market leader in innovative products, intended to inform our builders and trade centres.

The use of the word “Hoop Iron” amongst builders, trade centres and suppliers has become common and almost defining what products are being used, in Structural & Non-Structural applications. What builders and Trade Stores call Hoop Iron, can sometimes be easily mismatched with what suppliers have defined as Strapping or Bracing. Do we really know what is what? VUETRADE as a market leader in innovative products, intended to inform our builders and trade centres.

Often the name ‘Hoop Iron’ is used in the construction industry, that is effectively a flat steel sheet manufactured into lengths of specific width and thickness, then rolled up into rolls. This Hoop Iron product is commonly used in timber framing of houses in various connections and applications. However, due to the variation in sizes available in the range of Hoop Iron & the lack of understanding by the Building Trade, it often leads to thinking that a roll of Hoop Iron regardless of its profile is a Structural product. In fact, the usage of these straps in Structural or Non-Structural connections needs to be defined. Sizes that are commonly found in the market for Structural applications are 30mm x 1.2mm, 30mm x 1.0mm & 30mm x 0.8mm. Smaller sizes should not be considered Structural unless approved by a qualified engineer.

Hoop

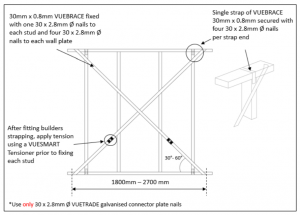

HoopThe framing code AS1684 – Residential timber-framed constructions stipulate walls must be braced in accordance with Table 8.18 specifically in 8.18 (b) & (d) involving metal straps to resist horizontal racking forces imposed to the building. The principle design of wall bracing is to have bracing strength equal to or greater than the racking forces imposed on a building face. The standard requires structural bracing of the wall shall use metal straps of minimum size 30mm (width) x 0.8mm (thickness).

This includes but not limited to: Tying down top plates to a wall stud, joining of top beams and ring beams, fixing of floor joists to bearers or top plate and others. AS1684 also requires these tie-downs to have a minimum metal strap dimensions of 30mm x 0.8mm.

With these two structural applications, it is easy to see some range of Hoop Iron does not meets the requirements to be a structural product, and often due to limited published information being available and awareness often leads to undersized Hoop Iron being used for structural purposes like wall bracing. Sizes such as a 25mm x 0.6mm or 25mm x 0.8mm hoop irons shall not be used for structural bracing or tie-down purposes, as these Hoop Iron sizes are often used for securing non-structural elements of a building such as piping, air-conditioning units etc.

VUETRADE actively educates and informs builders & tradies to understand the difference in strap sizes on the usability in different connection type. VUETRADE Brace Strap, with a minimum size of 30mm x 0.8mm, are suitable for applications like structural wall bracing and general structural tie-down, fully complies with all the requirements of AS1684 in minimum cross-sectional area, steel material and also sufficient corrosion protection.

VUETRADE Light-Duty Strapping covers the range of straps 25mm x 0.8mm and smaller, which are only intended to be used for Non-Structural use such as bracing outdoor fences or securing utility pipes in a building frame where important structural loads are absent.

It all comes down to what type of application, combined with the current Australian Standards.

It is up to products manufacture to name their products, however, is everyone’s job to comply with legislation. Following the structural engineer is the guide on what type of strapping or bracing builders should be using in each application.