Designing and bracing structural timber walls, subfloors and roof frames are an integral part of building design, especially during a structural frame.

Considering all forces that may influence the design and framing of a project, it is crucial to know the height and span where correct bracing is needed, as well as using compliant products are part of all crucial elements ensuring solid framing.

This article provides a brief explanation on the vast topic of bracing, specifically on structural wall bracing principles and racking forces that can influence a successful and sturdy frame.

Timber-framed houses are carefully designed and constructed to resist environmental imposed forces, such as dead loads (gravity) and wind loads. These loads must be thoroughly considered and implemented in the design of the house to ensure the long serviceability and safety of occupants. In Australia, AS1684 – Timber Framed construction code provides specifications and requirements that must be adhered to for construction to be deemed compliant and satisfy the building code.

One of the critical forces that AS1684 thoroughly discuss apart from gravity loads and wind loads is the racking forces. Wind pressure induced by wind produces a lateral load that tends to cause a structure to tilt or ‘topple over’ that can easily compromise the stability of a building. These lateral loads from racking force must be effectively transferred through the structure to the foundation of the building, occasionally strengthen and assisted by bracing products such as steel bracing straps.

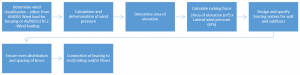

In order to design for bracing requirements needed to resist lateral racking forces, engineers and designers often refer to these procedures specified in the timber framing code AS1684, taking into full consideration of the environmental and building parameters to specify effective bracing design. The common steps specified by AS1684 clause 8.3 are as follows,

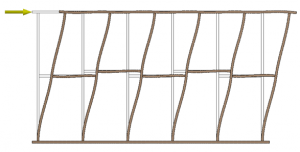

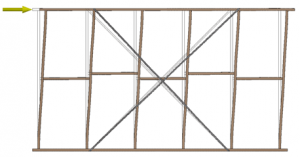

Bracing shall be provided on all structural faces of the building, such as walls, ceilings, subfloor and floors, however, this article will discuss specifically wall bracing only. The most common and effective means of providing wall bracing is by installing diagonal post-tensioned metal straps to timber frames. To meet the bracing capacity required, steel straps are required to be manufactured in strict specification in accordance with AS1684 with the specific net cross-sectional area, thickness, steel grade and corrosion protection. VUEBRACE Builders Strapping that is manufactured in Australia is one example of fully compliant steel straps suitable for structural wall bracing.

Steel metal straps such as VUEBRACE is suitable for wall bracing application, and when used in accordance with the application shown in AS1684 Table 8.18 (b) and Table 8.18(d) will provide the designated bracing capacity.

Wall capacity and height multiplier

AS1684 Table 8.18(b) and Table 8.18(d) provides bracing capacity that is applicable on the wall height of up to and including 2700mm. For any wall height that is greater than 2.7 meters, AS1684 cl 8.3.6.4 provided a multiplier table that engineers and designers can utilise in their wall capacity calculations.

[table “190” not found /]This article provides an introductory explanation on the vast topic of bracing, with a specific focus on structural wall bracing. Further articles and blogs will cover more details on different bracing requirements involving roof bracing and bracing installation guides.

References:

AS1684.2– Residential timber-framed construction, part 2: Non-Cyclonic Areas

AS1684.3 – Residential timber-framed construction, part 3: Cyclonic Areas