VUETRADE Speed Brace and how do you use them in roof bracing application?

VUETRADE Speed Brace and how do you use them in roof bracing application?

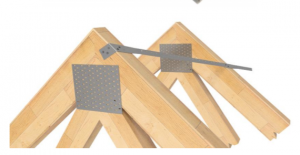

A pre-punched, rigid bracing primarily used for top chord roof bracing.

Manufactured and pre-formed angle for easy installation and guarantees excellent tension capacity.

VUETRADE Speed Brace is a bracing product designed specifically for roof bracing application in low wind speed conditions or cyclonic areas. Unique features of the Speed Brace allows the quick and effortless installation of bracing to roof trusses. Roof bracing is essential in resisting rotation and/or buckling of roof trusses that are often imposed by wind load or by the weight of the roof itself. Bracing of a roof are commonly done by using 2 metal straps installed diagonally following guidelines and requirements set out by Australian Standards such as AS1684.2/3 and AS4440.

VUETRADE Speed Brace is manufactured in pre-formed V-shape bend at an approximate angle of 120° to eliminate sagging along the length of brace for easy handling and installation, also removes the need of tensioning the brace during installation. [table “184” not found /]

How do I use VUETRADE Speed Brace for roof bracing application?

VUETRADE Speed Bracing shall be installed in an ‘X’ or ‘V’ pattern, running from the ridge to the eaves across the roof trusses. 30mm x 2.8mm diameter VUETRADE galvanised timber connector plate nails should then be driven through the pre-punched holes on each intersecting chord for effective bracing by allowing any lateral buckling load to be transferred to the supporting structures, thus keeping the roof assembly tight and square.

VUETRADE Speed Brace are engineered to suit installation recommendation set out by AS4440 for end fixing and strap splicing, with supporting documents and guidelines in the form of Technical Data Sheet TDS made available for download in the VUETRADE website product page.

VUETRADE Speed Brace comes in lengths of 4m, 5m or 6m and has a thickness of 1mm. VUETRADE Speed Brace is manufactured in Australia with G300 Z275 steel and fully complies with the corrosions requirement set by AS1684.