At VUETRADE we have our own facilities for testing our products, headed up by our engineer Danzel Teh. We feel it is important to have our own testing facility, speeding up product development and enabling us to run tests on products not just on a once off basis, but periodically, to ensure we’re delivering consistency.

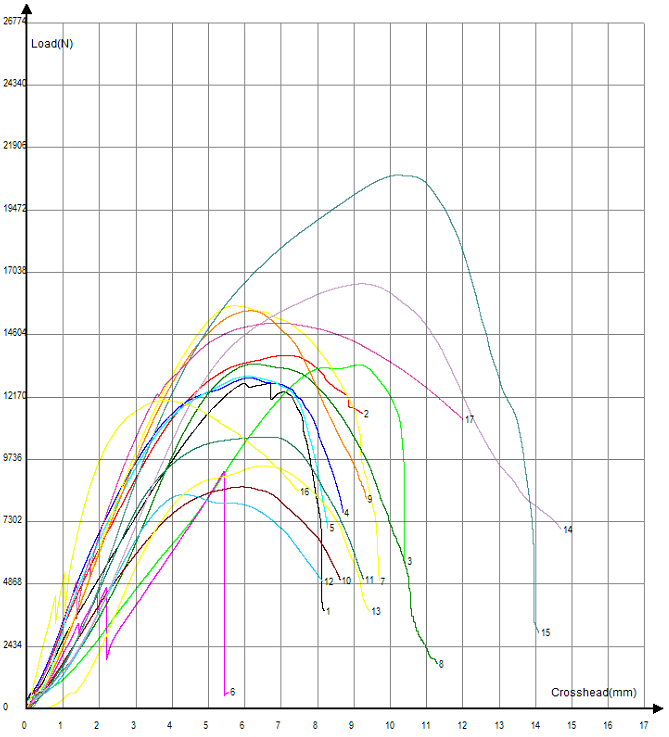

We have invested significantly in a MTS-SAN Universal Tensile Testing Machine which is calibrated regularly according to industry requirements (NATA). All product tests are performed in accordance to the Australian Standard relevant to the product/test performed. Through this machine, we are able to confidently provide reliable technical data for tradies and builders. As part of the research and development of VUETRADE products, new concepts are designed, manufactured and then tested to ensure the product meets the required standards and is safe for public use. VUETRADE’s technical team also monitors any updates and innovations with our products and ensures technical data for our products is readily available to our customers and up to date.

As well as testing to ensure our products are compliant, we also work on creating material and awareness around issues we find in the industry that directly relate to ensuring that the Australian Standards are met at all levels. One example of this is the work we are doing around how to comply with the AS1684.2 Bracing Code.

We are committed to our mission: ‘Empowering retail & trade outlets of any size, and tradespeople everywhere; with a comprehensive, innovative and quality range of products: backed by exceptional service and consistent supply.’ Our commitment to quality is shown in the major investments we make into our product development and testing program.