When you think about timber, we hardly think about where are they coming from, its nature, or the process that the timber goes through before they get to your preferred hardware store right?

When you think about timber, we hardly think about where are they coming from, its nature, or the process that the timber goes through before they get to your preferred hardware store right?

There are a few things that you can educate yourself on, which will help when choosing the right timber for a pergola, deck, or home project. It also helps when speaking with an architect, builder, or hardware store attendant when choosing between Traditional Timber and Engineered Timber. Do you really know the difference?

VUETRADE proudly provides innovative construction solutions to tradies & builders, especially in timber-framed construction. Often in our blogs we discuss various different topics regarding the usage of brackets & bracing used in timber framing, but never before on the primary structural component: Timber.

This article will briefly discuss timbers commonly used in Australia, as well as co-relate how VUETRADE products are often used to join and fasten timber members together, along with a brief engineering consideration needed for a safe joint assembly.

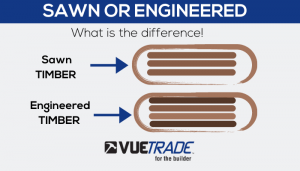

Timbers in Australia can usually be categorized into two main types based on manufacturing methods, namely sawn timber and engineered timber. Sawn timbers are often available as seasoned or unseasoned timber, and further classified as softwood or hardwood, depending largely on the density and the species. Engineered timber goes through additional process which improves the properties of traditional timber. Wood solutions provide a large database on the classification of timbers available in Australia, free to access by the public.

Timbers can be classified into groups or stress grade which allows timber to be used appropriately in structural applications, such as the construction of residential buildings. The industry term for these timber classification are called ‘structural grading’ and the two most common methods of grading timbers are visual stress-grading and machine stress-grading. In Australia, these grading methods are governed by industry standards such as AS/NZS 1748 & AS2082.

MGP grading system was introduced by Plantation Timber Association Australia in 1996 with a primary goal to produce accurate timber structure properties for designs. Commonly available timbers in the Australian market are usually graded in MGP10, MGP12, and MGP15 and typical strength characteristics have been documented in AS1720. Apart from the MGP grading system, sawn timber can also be graded in F-grade and A-grade which characteristics strength of these timber grades can be obtained from AS1720.1

Whenever the requirement of greater timber span is necessary, sawn timber often suffers from limited span lengths. Engineered timber products help close these gaps by specially engineered to allow a larger span with consistent properties and consistency. A few types of engineered timber products are Glulam, Plywood, Laminated Veneer Lumber (LVL), and Cross Laminated Timber (CLT). More detailed manufacturing methods will be discussed in future articles.

AS1684.2 and AS1684.3 provide the minimum requirements for framing specification, which is widely used as the primary standards for construction in residential buildings in Australia. This standard focuses primarily on timber framing using the aforementioned timbers grades along with recommended fixing methods using means of fasteners such as nails and screws. Engineered steel brackets such as VUETRADE Timber Connector products offer as an alternative solution to timber joining providing stronger joint design than traditional fastening methods.

The majority of VUETRADE timber connectors are innovatively engineered to suit the most commonly available timber grades. These products are designed based on requirements and recommendations of AS1720 – Design Methods that take into account of various capacity factors outline in the standard, which will effectively reduce or strengthen the design capacities of the products. An example of the usage of AS1720 as a design basis of VUETRADE products is on MGP10 Radiata Pine timber, which is readily available and widely used in Australia. MGP10 is classified in AS1720 to have a common joint group of JD4 where connector design capacities can then be determined using factors and requirements outlined in AS1720. Make sure you check out the product’s Technical Data Sheet.

Learning about the nature of timber would provide confidence in the timber specification that builders and architects often present, as well as understanding the important relationship between timbers and framing connectors. At VUETRADE, we aim to provide the building and construction industry with innovative and compliant products backed with accurate information.